Highly efficient gas filling

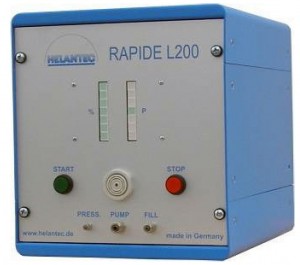

The RAPIDE L200 is a very efficient and manually operated gas-filling machine for filling insulating glass units. Equipped with highly modern and top-rated technology, the RAPIDE L200 makes it easy to fulfill requirements for quality assurance and quality documentation.

The RAPIDE L200 is a very efficient and manually operated gas-filling machine for filling insulating glass units. Equipped with highly modern and top-rated technology, the RAPIDE L200 makes it easy to fulfill requirements for quality assurance and quality documentation.

The RAPIDE L200 has been developed for universal application, not only including routine application but also special tasks such as samples, unusual shapes and dimensions. With its interfaces and connection possibilities, the L200 is prepared for a variety of future requirements.

Fast filling technology

The RAPIDE L200 uses fast-filling technology, which means filling amount and suction volume are synchronised. The reading of the internal pressure of the insulating glass unit regulates this process.

The increasing of pressure is lower when synchronization is more successful, resulting in less mixing and turbulence. This leads to reliable filling with lower gas loss and shorter filling times.

HELANTEC allows a pressure build-up of maximum 3 mbar inside the insulating glass unit. This special technique is based on many years of experience. Users especially appreciate the high controlling precision for large IG units.

Filling and monitoring

A gas analyzer, especially developed for this purpose by HELANTEC, monitors the filling process online. The gas analyzer is suitable for all gas types and gas mixtures used within the insulating glass industry.

The gas concentration is measured online during the filling process. The filling process is automatically stopped when the pre-set gas concentration is reached.

The gas-filling machine is available with one filling line.

The HELANTEC RAPIDE L200 provides:

- Reliable gas filling degrees and consistently high quality

- Fast filling and short manufacturing cycles

- Low gas loss

- Robust and tough in design and technology

- Various filling and suction probes available according to your requirements

RAPIDE L200 Specifications

- For gas filling in the production process for any gas types and gas mixtures

- Fast filling technology

- Synchronisation of filling speed and suction capacity by measuring internal pressure of the insulation glass unit

- Filling-lines: 1

- Capacity: Up to 20 liters per minute

- Technology microprocessor controlled

- Filling speed approximately. 12 liters/minute argon

- Pressure control inside IG unit is online, within milliseconds

- Gas injection pressure inside IG unit < 5 mbar

- Display of pressure inside IG unit is online with LEDs

- Concentration measurement is online with special integrated analyzer

- Concentration display is online with LEDs

- Stop of filling process is automatically as soon as the adjusted gas concentration is reached (factory made and adjustable between 70% and 100% – typical 90%)

- Calibration of the analyzer is semi-automatic with calibration mode (needs 10 seconds only)

- Accuracy of analyzer is better than 2% abs.

- 1 particle filter, installed outside and easily interchangeable

- Gas input :1

- Gas input pressure: 3 bar

- Gas input pressure control is optical and acoustic (if bottle pressure < 1 bar)

- Power supply 230V

- Dimension: 11 x 13.8 x 12.6 inches

- Weight: approximately 22 pounds

- Special accessories are available for special applications